- Home »

- Тechnology

Thermoelectric cooler (TEC) construction

The first thermoelectric phenomenon was discovered by French physicist and meteorologist Jean Peltier (1785-1845). The basic idea behind the Peltier effect is that whenever DC passes through the circuit of heterogeneous conductors, heat is either released or absorbed at the conductors' junctions, which depends on the current polarity. The amount of heat is proportional to the current that passes through conductors.

As a result of works performed by Russian academician A.F. Ioffe and his colleagues the semiconducting alloys were synthesized allowing to apply this effect in practice and to begin the full-scale production of thermoelectric refrigerating devices for wide use in various fields of human activities.

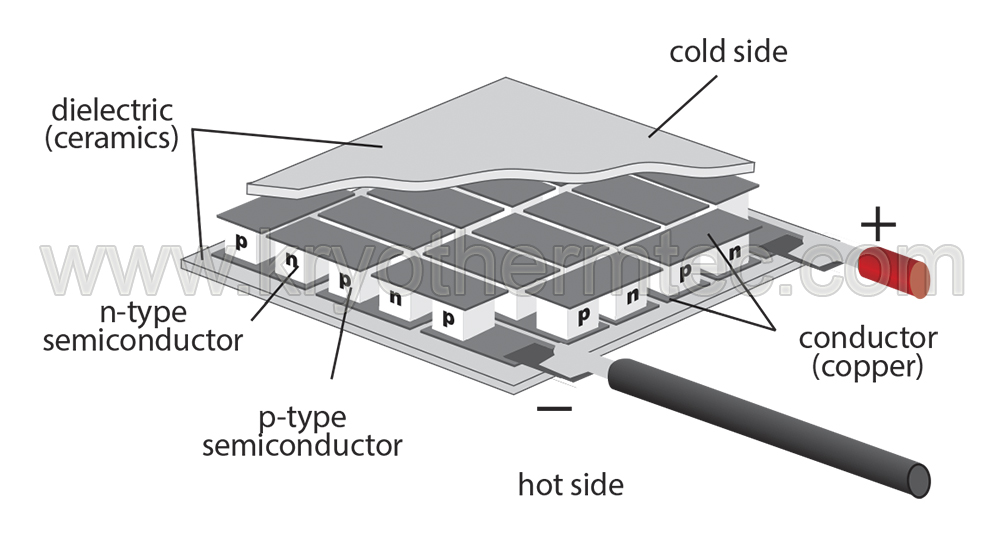

The basic thermoelectric (Peltier) cooler unit is a thermocouple, which consists of a p-type and n-type semiconductor elements, or pellets. Copper commutation tabs are used to interconnect pellets that are traditionally made of Bismuth Telluride-based alloy.

The basic thermoelectric (Peltier) cooler unit is a thermocouple, which consists of a p-type and n-type semiconductor elements, or pellets. Copper commutation tabs are used to interconnect pellets that are traditionally made of Bismuth Telluride-based alloy.

Thus, a typical thermoelectric cooler (TEC) consists of thermocouples connected electrically in series and sandwiched between two Alumina ceramic plates. The number of thermocouples may vary greatly - from several elements to hundred of units. This allows to construct a TEC of a desirable cooling capacity ranging from fractions of Watts to hundreds of Watts.

When DC moves across Peltier cooler, it causes temperature differential between TEC sides. As a result, one thermoelectric cooler face, which is called cold, will be cooled while its opposite face, which is called hot, simultaneously is heated. If the heat generated on the TEC hot side is effectively dissipated into heat sinks and further into the surrounding environment, then the temperature on the thermoelectric cooler cold side will be much lower than that of the ambient by dozens of degrees. The thermoelectric coolers cooling capacity is proportional to the current passing through it. TEC's cold side will consequently be heated and its hot side will be cooled once the TEC's polarity has been reversed.

Kryotherm single-stage thermoelectric coolers permit to obtain the temperature difference up to 74-76K. To obtain lower temperatures multistage TEC's are used. For example, maximum temperature difference of one of the serial Kryotherm four-stage TEC's is 140K.