- Home »

- Products »

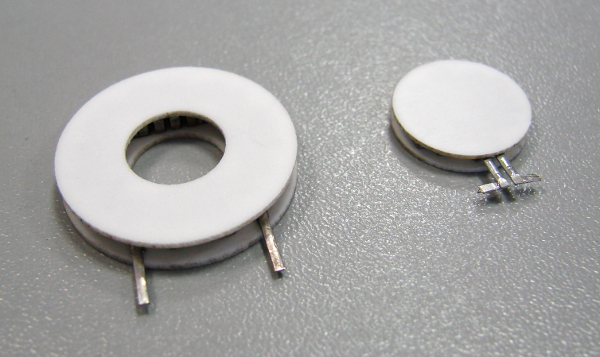

- Thermoelectric (Peltier) coolers »

- Thermoelectric coolers for industrial applications

Thermoelectric coolers for industrial applications

Thermoelectric coolers for industrial use face higher requirements in efficiency, reliability, production accuracy and field performance data. They designed to be used in the industrial systems of cooling and temperature control.

Special TECs (with С index) are produced for operation under temperature cycling conditions – rapid periodic (up to hundreds of thousands of cycles) changes of temperature of one or both sides of thermoelectric cooler in a wide (several tens of degrees) range of temperatures.

We also produce thermoelectric coolers designed for operation in high temperatures, pressures, humidity.

Main fields of application:

- Industrial electronics and telecommunications

- Thermoelectric cooling assemblies and conditioners with different functions

- Thermoelectric cooling devices for cupboards and electronic equipment blocks

- Systems of temperature control of the critical parts and components of different lathes and machines

- Heat flow probes

- Medical equipment

- Transport

- Food industry

Thermoelectric modules and systems, produced by “Kryotherm”, fit all the modern industrial standards and special requirements. The quality and reliability of TECs are verified by numerous tests performed according to the system of quality accepted at the enterprise. Every batch of TECs is produced in one-to-one correspondence with the customers’ specification and is tested according to a program, confirmed by the customer.

Environmental Safety Features

According to RoHS directive requirements, thermoelectric coolers do not contain lead or any other forbidden materials.

Abbreviations and definitions

| TEC | thermoelectric cooler |

| TGM | thermoelectric generating module |

| DTmax | maximum achievable temperature difference between the hot and cold side of a thermoelectric cooler |

| Imax | input current through a thermoelectric cooler resulting in greatest DT (DTmax) |

| Umax | voltage on a thermoelectric cooler contacts at DTmax |

| Qmax | maximum cooling capacity of a thermoelectric cooler. It is determined at maximum current through a thermoelectric cooler and at zero temperature difference between hot and cold sides |

| Rac | electric resistance of a thermoelectric cooler measured at an alternating current with the frequency of 1 kHz |